Searching for a specific product for your next project? View all our custom-build solution categories below.

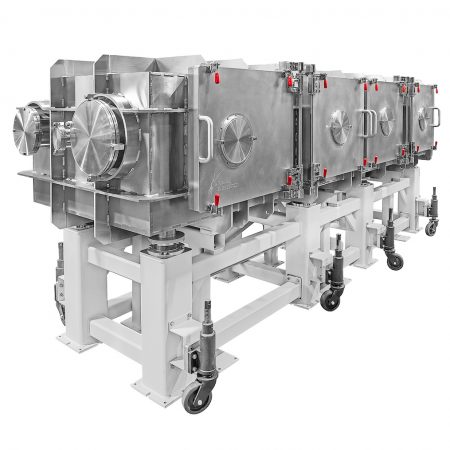

From one-time custom equipment builds to repeat manufacturing and delivery of process modules and systems, our team specializes in engineering and fabricating large-scale projects. We fabricate vacuum chambers, weldments, and related components of virtually any size or complexity using the latest engineering and design software, advanced modeling, and analytical tools.

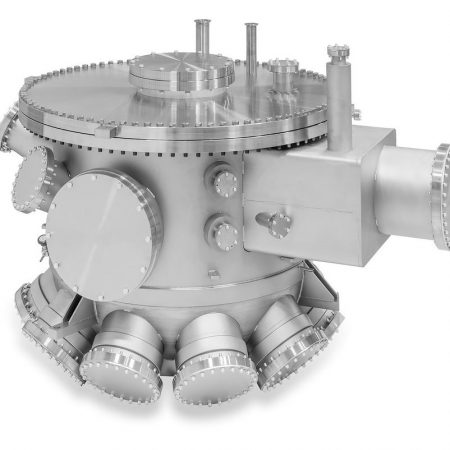

Vacuum chamber fabrication using specific processing techniques is critical to producing any Extreme High Vacuum (XHV) system. Each application has different factors relating to chamber design, material options, processing techniques, and chamber manufacturability. Anderson Dahlen designs and manufactures custom chambers, welded assemblies, flanges, and precision components for XHV requirements.

Anderson Dahlen offers years of engineering and manufacturing experience for Ultra-High Vacuum (UHV) chambers and components used in applications such as surface analysis, mass spectroscopy, feed-throughs, and accelerator beamlines.

Flanges and components are critical to any high vacuum (HV) or ultra-high vacuum (UHV) system. Standard components are convenient but are only sometimes the optimal solution. When standard parts are insufficient, Anderson Dahlen has the engineering and manufacturing capabilities to produce the ideal product to meet your requirements.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795